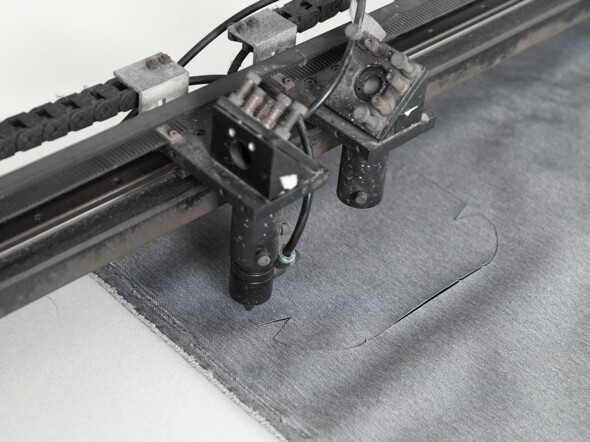

With the laser cutting machine, we can manage different shapes and fabrics with extremely precise cutting and high-efficiency, which can greatly contribute to quick lead time and minimal costs.

That is why Kin Wo is so confident in the lead time and the quality of custom made bags.

Supported by well-trained seamers and the computerized sewing machine, we can easily produce complex and fine stitching sewing.

Compared with the traditional sewing machine, the efficiency of utilizing the computerized sewing machines can be increased by up to 30%~50%.

Therefore, we possess the ability to manufacture large volumes of bags, yet still, ensure quality and quick delivery.

To ensure top quality bags, apart from the incoming raw material tests to the in-processing tests, a full product inspection will be conducted before delivery to ensure the top quality of our custom made bags are met.